Casting is a common manufacturing process used for producing various engineering parts across different industries. The casting process involves pouring molten material into a mold, allowing it to solidify, and then removing the finished product from the mold. Different types of casting methods are employed based on the material, complexity, and size of the part.

Description

Here are some common casting methods used for engineering parts:

Sand Casting:

Process: In sand casting, a mold is created using a pattern made of wood, metal, or other materials. Sand is packed around the pattern, and then molten metal is poured into the mold.

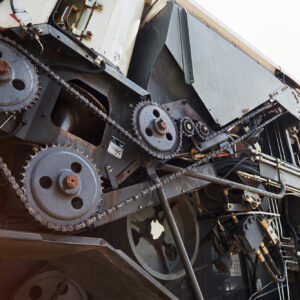

Applications: Sand casting is suitable for large and complex parts, such as engine blocks, cylinder heads, and other components with intricate shapes.

Die Casting:

Process: Die casting involves forcing molten metal into a mold cavity under high pressure. The mold, called a die, is typically made of steel and can produce parts with high accuracy and surface finish.

Applications: Die casting is commonly used for producing components with complex geometries, such as automotive parts, electronic housings, and consumer goods.

Investment Casting:

Process: Investment casting, also known as precision casting, involves creating a wax or plastic pattern that is coated with a ceramic shell. The shell is then heated to remove the wax or plastic, leaving a cavity for molten metal.

Applications: Investment casting is suitable for intricate and high-precision parts, such as aerospace components, jewelry, and dental implants.

Lost Foam Casting:

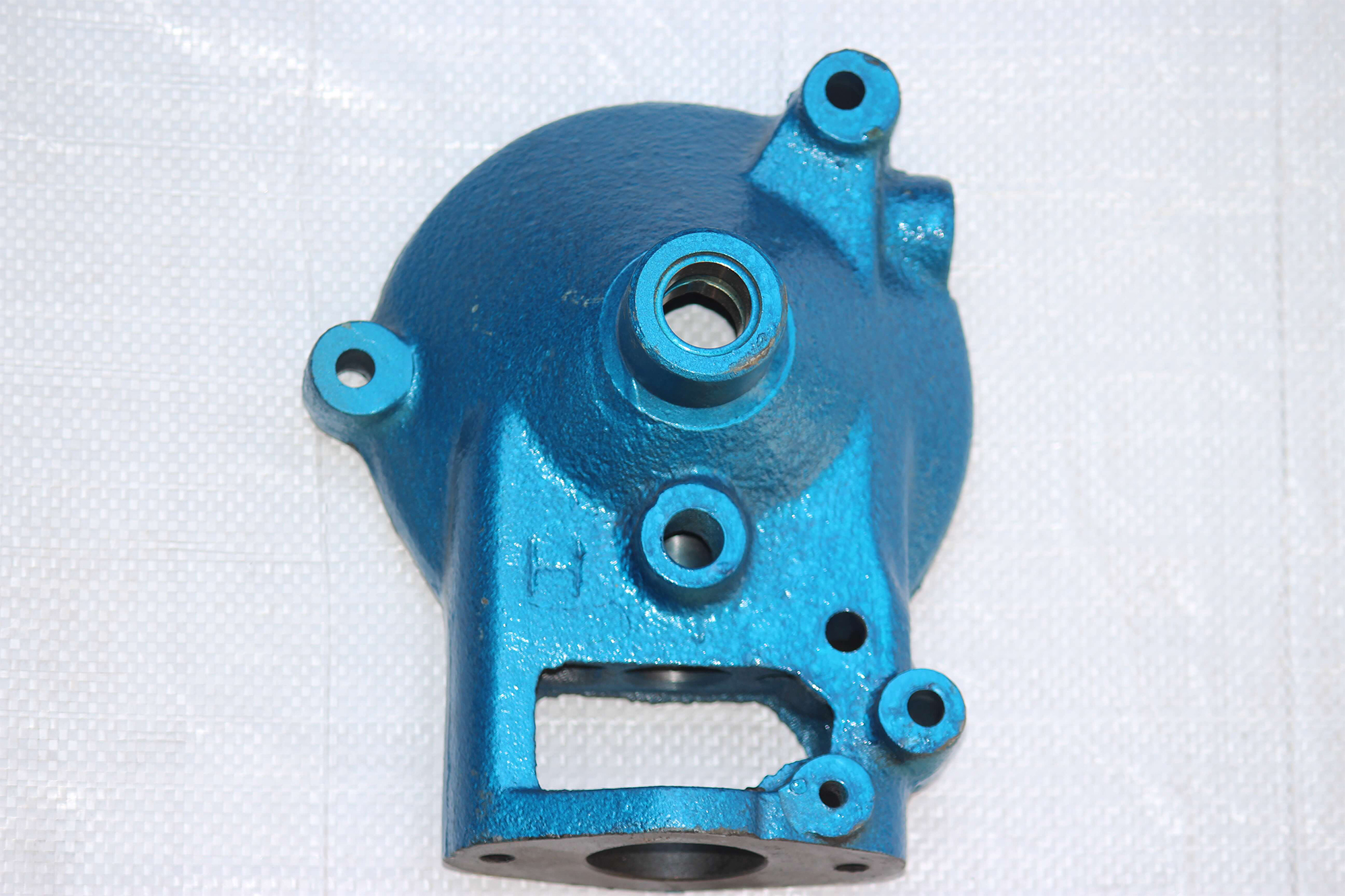

Process: Lost foam casting involves creating a foam pattern of the desired part, which is then coated with a refractory material. The coated pattern is placed in a mold, and molten metal is poured into the mold, vaporizing the foam and filling the cavity.

Applications: Lost foam casting is used for producing complex and lightweight parts, such as automotive engine components and pump housings.

Centrifugal Casting:

Process: In centrifugal casting, molten metal is poured into a rotating mold. Centrifugal force distributes the metal along the mold walls, creating a cylindrical or tubular part.

The choice of casting method depends on factors such as the material properties, part complexity, production volume, and desired surface finish. Each casting method has its advantages and limitations, and engineers select the most appropriate method based on the specific requirements of the engineering part being produced.